Esperanto

Esperanto

Shqiptare

Shqiptare

Euskara

Euskara

Zulu

Zulu

Latinus

Latinus

Cymraeg

Cymraeg

தமிழ்

தமிழ்

Slovak

Slovak

Slovak

Slovak

Afrikaans

Afrikaans

Innovation team and platform

The company has an experienced and technically proficient product design and development team, the headquarters has more than 300 engineering and technical staff, including 5 professor-level senior engineers, 46 senior engineers, and 140 people with intermediate titles or above. It has more than 40 independent intellectual property rights and more than 10 high-tech products.

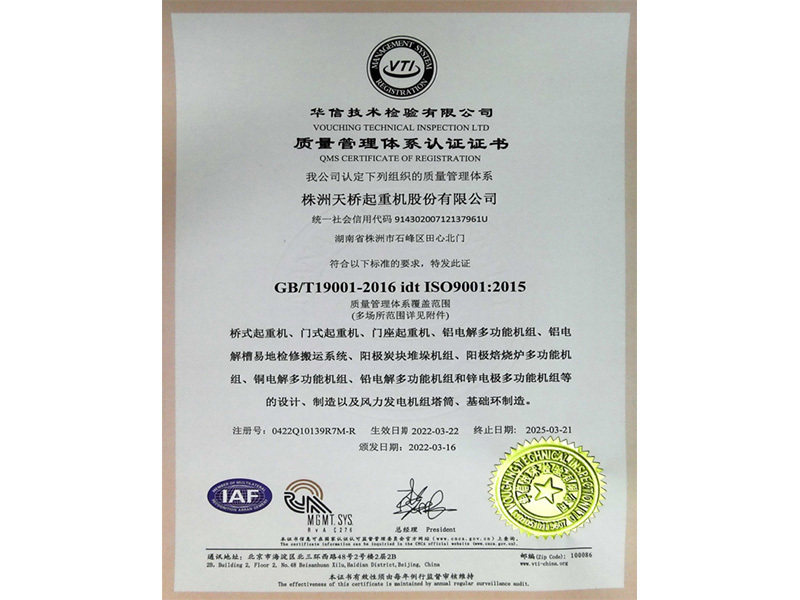

ISO9001 Series International Quality Management System Certification

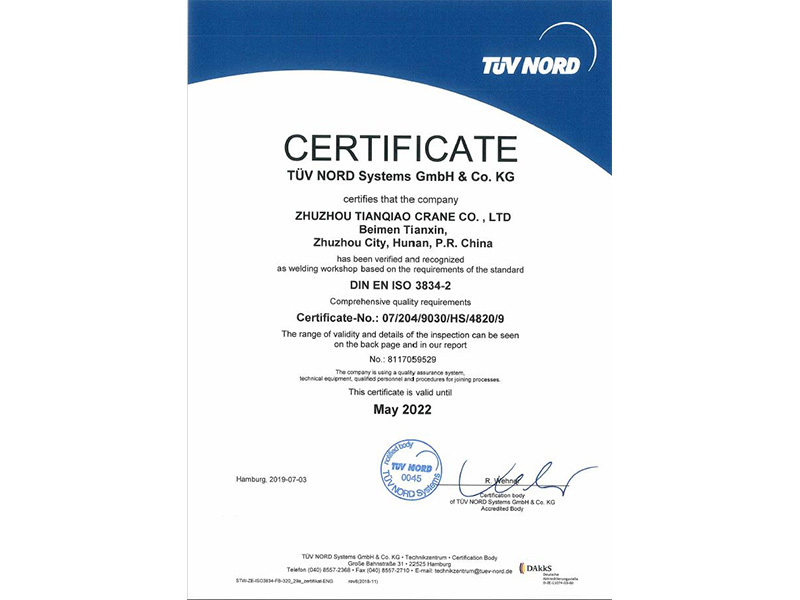

International Welding System 3834

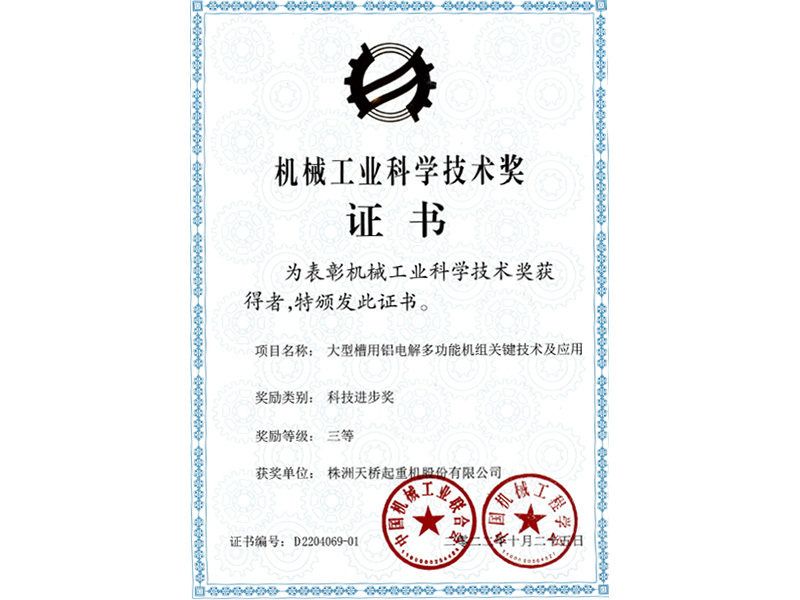

Science and Technology Progress Award

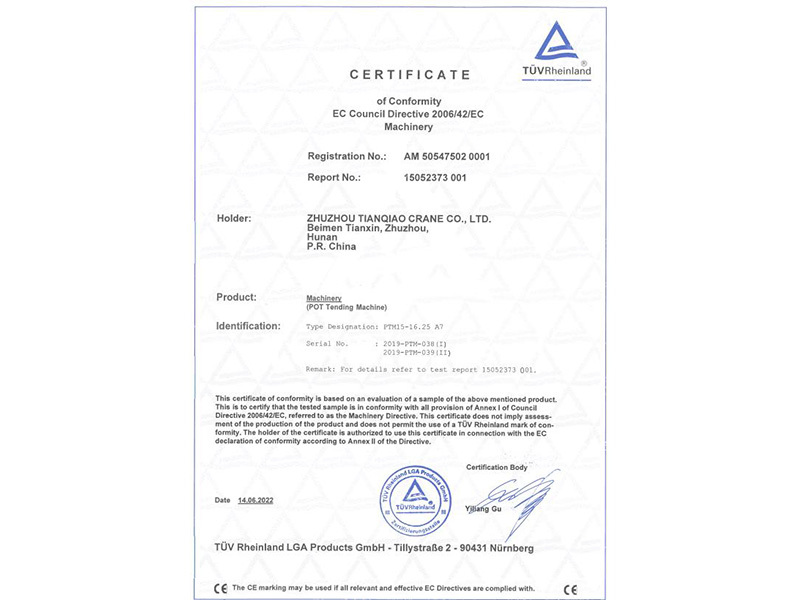

EU CE certification

High tech enterprises

Engineering Technology Research Center

National Technological Innovation Demonstration Enterprise

Hunan Metallurgical Material Handling Equipment Engineering Technology Research Center

Hunan Intelligent Lifting Equipment Industrial Design Center

Benchmark enterprise for the integration of industrialization and industrialization

National Manufacturing Single Champion Product

Provincial Enterprise Technology Center

Software strength

The company has industry-leading design software application capabilities, mainly using design software such as Haochen CAD, SOLIDWORKS, etc; The main design analysis and calculation software includes SimulationX, etc; Combined with the application of the above software, virtual prototype modeling and digital simulation research are carried out on the key common technologies and core issues of cranes, including dynamic analysis, statics analysis, system simulation analysis, electromechanical hydraulic integration analysis and other research. At the same time, we will vigorously promote the application of CAPP process systems.

The product service cloud platform is committed to collecting real-time data, device status, faults, alarms, and other information during device operation, and synchronously uploading them to the local monitoring center. It utilizes key technologies such as multi bus and multi state data collection, wireless communication, embedded, condition based maintenance, GPS, dynamic web pages and big data storage, data analysis, and cloud computing to collect, monitor, and store lifting equipment in real-time, By utilizing the advantages of professional performance indicator analysis and information automation, we can provide massive data or services for personnel in design (testing/analysis), production, maintenance, sales, customers, and other roles. Through data mining, we can optimize equipment performance and ultimately achieve the goal of value-added enterprise services.

The technology center designs a collaborative platform for simulation product research and development, which uses modularization as the design foundation and parameterization as a means of module transformation. Combined with the actual needs of the enterprise, modular analysis, processing, and parameterization modeling are carried out to form a standardized and reusable resource library for the enterprise. A product design collaborative platform with PLM as the core is established to achieve configuration design and variant design, thus achieving rapid design, Enhance the ability to innovate technology and products, and promote the modularization and standardization of design for single piece, small batch, and customized production enterprises.

The company started early in information technology construction and established communication systems such as local area network instant messaging software and email systems internally, achieving data sharing and resource utilization of product information and enterprise resources. Product quotations, design drawings, and documentation are all completed using local area networks. At the same time, we have successively run the OA collaborative office system, ERP system, product design data system, and CAPP process management system, improving the company's research and development and management level.

Hardware strength

The company has an experienced and technically proficient product design and development team, the headquarters has more than 300 engineering and technical staff, including 5 professor-level senior engineers, 46 senior engineers, and 140 people with intermediate titles or above. It has more than 40 independent intellectual property rights and more than 10 high-tech products.

Follow Us